Safran modernises its MRO resources in Tarnos |

| Léo Barnier in Tarnos |

|

|

27 FEB 2020 | 481 words

|

|

© Safran |

|

|

|

Safran Helicopters Engines rolled out the red carpet at Tarnos (France) on 21st February. Ross McInnes, Safran's Chairman of the Board, Philippe Petitcolin, the group's Chief Executive Officer and Franck Saudo, the CEO of Safran Helicopter Engines were all present to welcome the French Armed Forces Minister Florence Parly who had come to inaugurate the CAP 2020 industrial campus. This is the name of the project to modernise the Tarnos site and which is intended to significantly increase its MRO productivity, which is mainly geared towards the French armed forces' helicopter fleets.

"This is the flagship of our support and services activity", said Franck Saudo when presenting Tarnos, the second-largest Safran Helicopters Engines site and the engine manufacturer's main maintenance facility. The site opened in 1965 and now requires major modernisation. And this is what CAP 2020 is providing.

Officially launched in September 2015, the CAP 2020 project saw the construction of three new buildings which were delivered last year. The first is an 8 500 m² industrial hangar which houses the parts and components repair shop (CEPRC). The second has 14 500 m² dedicated to servicing and repairing the actual engines. And the last building houses tertiary activities to manage the Safran Helicopters Engines worldwide support network, which has 15 international subsidiaries. Franck Saudo feels that the company has "the most modern helicopter engine support facility in the world".

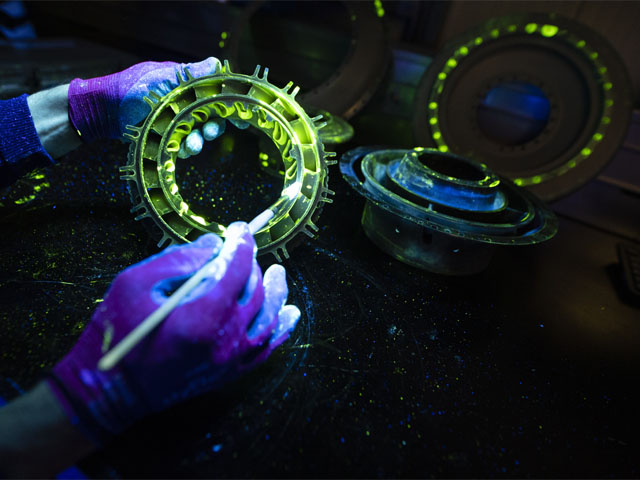

New technologies have been deployed for component repair. © Safran / CAPA / L. Pascal

New technologies have been deployed for component repair. © Safran / CAPA / L. Pascal

Increases in productivity

The project is based on two key elements, which were outlined by the Safran Helicopter Engines boss. The first element is the modernisation of the industrial resources and the second is production line flow optimisation. The grouping together and linear reorganisation of the engine handling process reduce the circuit to less than 500 m where a machine might travel over 5 km previously. Franck Saudo also claims a 30% reduction in MRO cycles. This takes the average time to repair or service an Arriel or Arrius engine down from 50 to 35 days.

While the savings are significant, so is the investment. The Safran group has self-financed 50 million Euro to put CAP 2020 in place. And it has committed an additional 9.5 million Euro for the second phase which will see the modernisation of new part production, with the requalification by 2022 of an existing building which is currently unused.

The Tarnos site targets the Europe, Africa and Middle East market, which represent an installed fleet of 5 000 engines from 350 operators in 85 countries. Its main customer is the French government, which alone accounts for 1 600 engines in under its MCO performance contract, which covers the fleets of the French armed forces, the Gendarmerie, Customs and civil security. Each year, Tarnos handles some 650 civilian and military engines, including one hundred under this government contract. Around 20 000 parts and accessories are added to this.

|

|

|

Léo Barnier

Specialized journalist

Industry & Technology, Equipments, MRO

|

|

| |

They made this section possible |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Top stories |

|

|

|

|

|

Top stories

|