Collins Aerospace unveils its Singapore Innovation HubRomain Guillot in Singapore Collins Aerospace took advantage of the Singapore Airshow opening to announce the creation of a dedicated innovation hub in the Island State, with a direct link to its facilities near Changi airport. It will use digital sciences to help improve its worldwide MRO services.

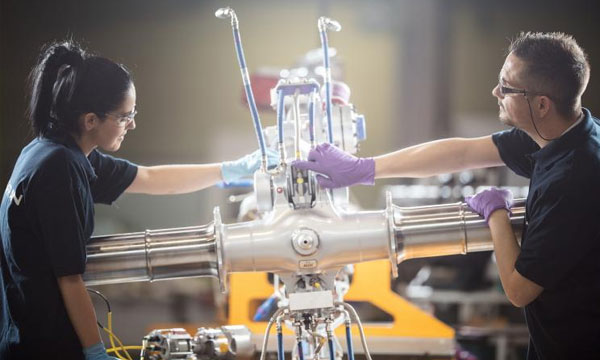

In particular, the new Collins Aerospace Systems' Singapore Innovation Hub will be dedicated to robotics, automation and data science, with major technological returns which will standardise and optimise the tools and processes which are currently being used in the equipment manufacturer's worldwide MRO network within five years, benefiting airlines. Collins Aerospace has even committed to providing over forty proof-of-concepts over the next five years. "This is a major step for us", said a happy Bob Butz, general manager and vice president, Global Repair Services at Collins Aerospace. He announced that a 10,000 square foot facility is now dedicated to innovation in Singapore. "But this direct link to our Singapore Service Centre means that it's almost as if we had an even bigger lab", he explains to us. He also reminded us that Collins Aerospace established a base in the Island State in the early 70s and has continued to invest there, boosted by the very high levels of labour, but also by the business environment in Singapore. "These were also major catalysts for the creation of the hub", he tells us. The Singapore innovation hub will employ nearly forty highly skilled profiles. Bob Butz also explains that the proof-of-concepts will not just cover services, with the possibility of also seeing them adopted more widely by some the 300 Collins Aerospace production facilities. "We feel that the hub is really marks the foundations of our MRO shop of the future", he states. "We really want to advance certain everyday activities towards activities with higher added value". He also notes that the repairs are increasingly complex while at the same time customers need more visibility by remaining connected throughout the process. Therefore, according to Bob Butz, the maintenance shop of the future is based around three major concepts. The first is "customer connectivity", which enables interactions to be improved and sped up (customer portal, improvement of stock management and part availability, supply of repair prognosis elements and so on). Next, there is the "integrated operations" concept, which is dependent on the first concept and which will reduce a large number of processes which are currently carried out manually, thanks to optical reconnaissance, robots, real-time RFID part location and so on. Finally, the last concept is the use of the very high volumes of data present almost everywhere in maintenance to bring unified tools to save time during the decision-making processes. Note that the Singapore innovation centre is also intended to become one of the three centres of excellence for Collins Aerospace's additive manufacturing technologies, even if Bob Butz says that this type of part production is still heavily dependant on the certification constraints of the different authorities. |

||||||||||||||||||||||||||||||||||||||||

Partager cet article : |

||||||||||||||||||||||||||||||||||||||||

Dans la même thématique |

||||||||||||||||||||||||||||||||||||||||

Collins Aerospace Bob Butz Singapore Innovation Hub Singapore Airshow 2020 |

||||||||||||||||||||||||||||||||||||||||

l'actualité aéroNAUTIQUE à LA UNE |

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||