Lufthansa Technik wants to simplify cabin seat maintenance |

| Emilie Drab |

|

|

29 NOV 2018 | 298 words

|

|

© Lufthansa Technik |

|

|

|

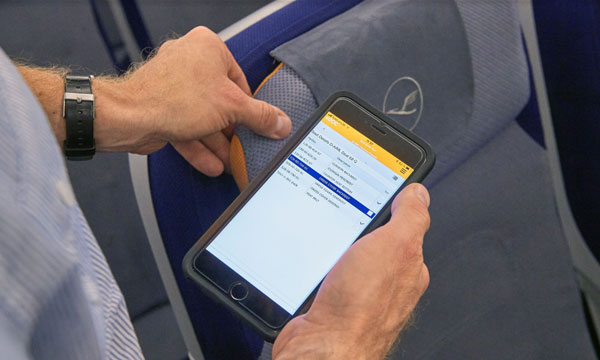

On 19th November, Lufthansa Technik unveiled a new system to improve seat maintenance. Available for PC and mobile devices, this "Digital Seat Cover Tool" is the first digital assistance system which enables an operator to identify seat cover part number sin the world. For now, it is only be used on Lufthansa's A380 fleet.

The German Airline MRO explains that until now the maintenance process was fully manual, whether for detecting damaged equipment (cover, cushion or belt) or for identifying its reference, order or replacement. With the "Seat Cover Tool", part of the process is automated, making it easier to speed up identification and replacement. "We have managed to reduce the process from six to under one minute", says Stefan Mehler, project director at Lufthansa Technik.

Lufthansa Technik is now working to expand the scope of its new tool to extend it to other equipment and other types of aircraft as early as next year. It is then planning to market it to other MRO companies.

The company is working to provide more visibility in the cabin in terms of maintenance, a problem which affects all operators but one which is not often highlighted. But other companies are also looking into the question, such as the RFID label manufacturer Brady, which has launched the RFID Air labels which should facilitate life cycle management for cabin equipment in particular.

One other major project is underway in this area and was unveiled by the company's competitor Diehl Aviation in the spring: iCabin - for intelligent cabin. The approach is a different one and involved developing a connected cabin which tells the operator which equipment isn't working, avoiding inspections which take time and personnel and enabling maintenance work to be scheduled more easily.

|

|

|

Emilie Drab

Assistant editor

Civil aerospace, Air transport

|

|

| |

They made this section possible |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Top stories |

|

|

|

|

|

Top stories

|