Support: How Boeing's 737 MAX family is entering the data analytics age |

| Romain Guillot |

|

|

20 SEP 2018 | 807 words

|

|

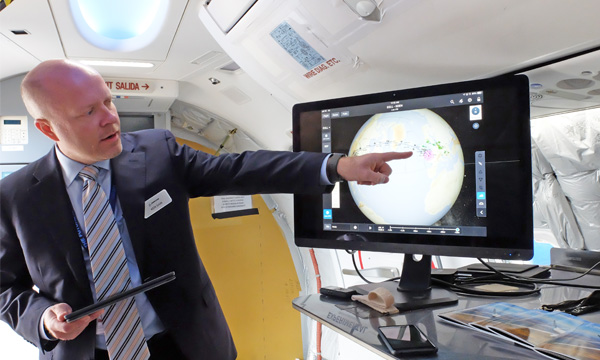

Ken Sain, Vice President Digital Aviation & Analytics at Boeing Global Services (BGS). Picture © Le Journal de l'Aviation - All Rights Reserved |

|

|

|

Boeing Global Services (BGS) hosted a select group of journalists onboard the first test 737 MAX 7 at Farnborough to present the range of services which now accompany Boeing's latest generation of single-aisle aircraft.

One year on from the creation of Boeing AnalytX, a new division dedicated to data across Boeing's commercial, defense and services businesses, Ken Sain, Vice President Digital Aviation & Analytics at Boeing Global Services (BGS) highlights the different progress that has been made between the 737NG and 737 MAX families in terms of support, in particular with the increase in data collection processes in and around the aircraft.

Of course, the Boeing 737 MAX introduces new features which enable much more information to be generated for airlines. But Ken Sain explains that the performances and efficiency of a fleet can really be maximised by adding ground support solutions.

For example, he mentions the functionalities from the aircraft's new flight deck, which certainly preserves the commonality with the previous generation but which is much more advanced and has features similar to those available on the Dreamliner family. The 737 MAXes are also equipped with a new onboard server (ONS) which is much more advanced than the one on the 737NGs, with a host of tools geared towards maintenance. "It's a real virtual CMC", he explains (Central Maintenance Computer). The new single-aisle planes also have a new onboard diagnostic tool (On board Management Agent), which monitor all of the aircraft's parameters and data in real time and which can identify potential failures.

Ken Sain also explains that the 737 MAXes are delivered with a full SDK (Software Development Kit) that may be used by third parties (for example for applications that have already been developed by airlines and which may be used onboard the aircraft). The fourth generation of Boeing 737s also comes with secure wireless connectivity, to both upload the aircraft's own software applications and to update the data needed for navigation and which will be used by the FMC (Flight Management Computer). Conversely, this connectivity enables the aircraft's data to be captured for use at operations level, like the data collected by a QAR (Quick Access Recorder) or an FDR (Flight Data Recorder).

Boeing has also completely overhauled the ground support environment by organising how the different types of data are accessed. "Generally speaking, what happened before was that we attached a maintenance laptop computer to the aircraft to troubleshoot and identify problems which would develop into failures, whereas now we can do it all wirelessly".

But Ken Sain insists on the fact that these new features, which already enable the aircraft to create more value for the customer, will be improved further with the addition of digital data analysis solutions, which will make even more effective fleet operations possible.

He takes the example of the crew management solutions provided by Boeing. A third of the Boeing 737 MAX fleet which will be delivered will actually be piloted by crews managed by the aircraft manufacturer's crew optimisation solutions (composition, rostering, etc.), which will enable the airline to manage its schedule and improve its efficiency. Boeing's crew management solutions already cover 400 000 members of crew around the world. "This enables productivity to be increased by between 3% and 7%, for example by operating with more aircraft with the same amount of crew or simply by being more effective thanks to an optimisation algorithm, while of course continuing to take account of crew preferences with a preferential betting tool", specifies Ken Sain.

This is also the case for flight plan creation, a sector where Boeing has one of the three main solutions in the world (JetPlanner - Jeppesen), with some 700 customers and 1.1 million flight plans generated each month at the four corners of the globe. "Our tools manage to generate between 1 and 3% in improvements, whether for fuel use, over-flight rights management and so on", he adds, at the same time reminding the journalists present that for the 737 MAX family, one plane in three will also be covered by Boeing's flight planning solutions. This is even more so for the EFBs where three 737 MAXes in four will be delivered with electronic flight bag solutions that use Boeing applications. The American aircraft manufacturer also provides support from some 300 000 touch tablets.

Data is therefore collected at every level (flight preparation, dispatch, flight trajectory, Airplane Health Management and so on) before being analysed by the various Boeing AnalytX tools. Customers are then offered specific services for each airline department, whether for crew monitoring, flight planning or maintenance.

So, just for maintenance alone, Boeing"s analysis tools also take account of the plane's data from Airplane Health Management (AHM) of course, but also the Toolbox application, the Aerdata documentary management tools (STREAM, EFPAC) or the MyBoeingFleet platform.

With the MAX, the 737 family is also now entering the data analytics age.

|

|

|

Romain Guillot

Chief editor

Cofounder of Journal de l'Aviation and Alertavia

|

|

| |

They made this section possible |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Top stories |

|

|

|

|

|

Top stories

|